1. Intelligent Cold Chain Storage

① Multi-temperature Zone Coverage:

Freezer: It can maintain ultra-low temperature storage at -18℃ to -25℃ all day long, and has 2,700 automatic pallet storage locations + 344 traditional manual storage locations, specially for high-demand categories such as frozen meat, seafood, and ice cream.

Refrigerated warehouse: It can achieve precise temperature control from -5℃ to 10℃, has a storage capacity of 300㎡, and has four floors with a total of 380 pallet positions that can be flexibly turned over, suitable for fruits, vegetables, dairy products, etc.

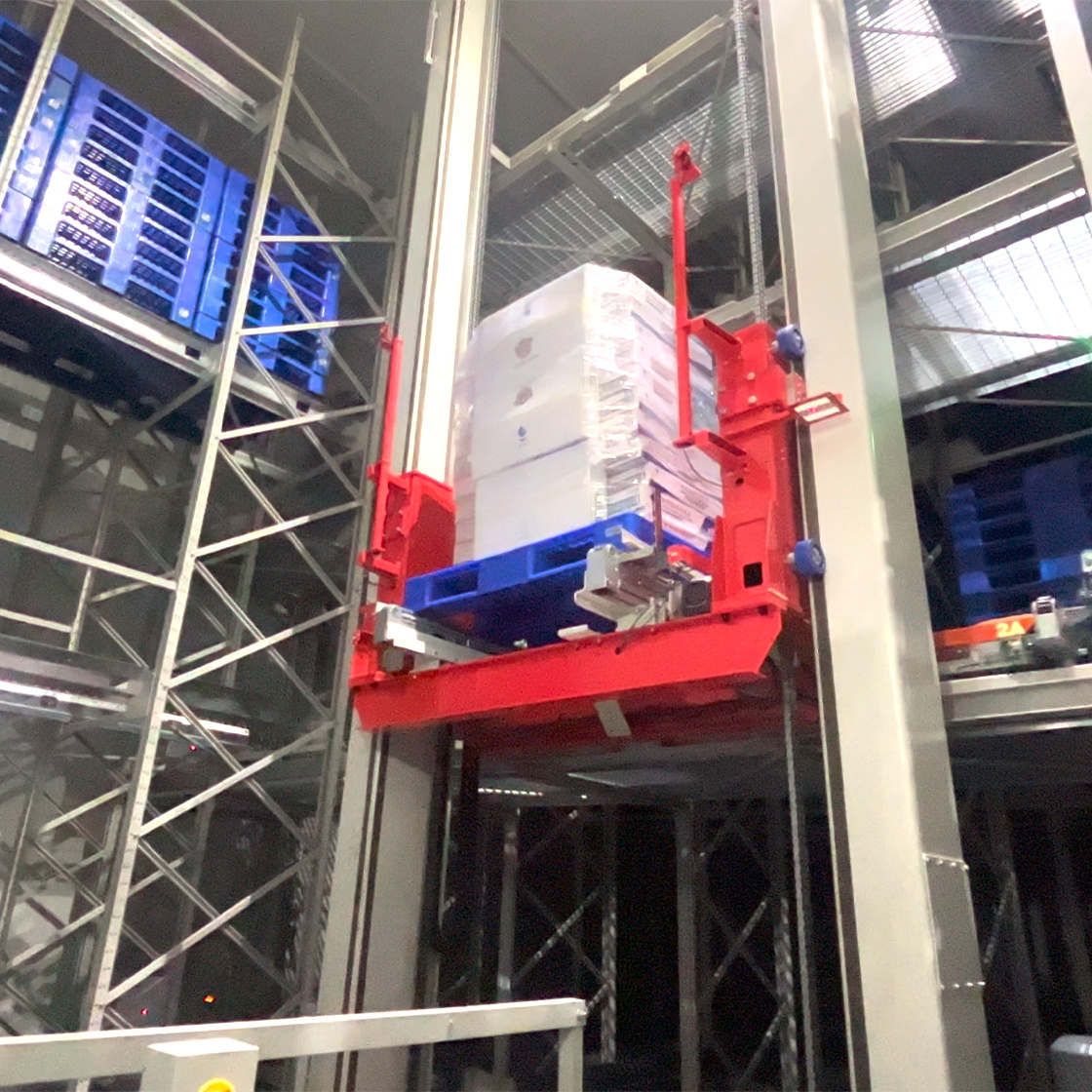

② Fully Automated Operation:

Using high-level shelves + Mother-child shuttle car + WMS/WCS intelligent system to achieve unmanned storage and retrieval in the freezer, with inventory accuracy ≥99.9%.

Conveyor belts and elevators operate in conjunction, with a daily throughput of 200 tons, greatly improving peak efficiency.

2. Bonded Integrated Services

Inspection and Transfer: Seamless connection between the customs-designated inspection site and the bonded cold storage, supporting the "arrival-inspection-distribution" of frozen goods for express customs clearance within 8 hours.

Processing and Distribution: Standardized operating areas are configured within the warehouse, providing value-added services such as sorting, labeling, and gift box packaging for frozen goods, with a nationwide T+1 delivery network.